Protect Your Medicines with TPB’s Secure Custom Medicine Boxes

The Packaging Base offers long-lasting custom medicine boxes to protect your medicine from bacteria and other damage. These cases are manufactured with different heavy-duty cardboard, corrugated, and kraft materials. With a variety of stocks available, choose the one according to your medicine type. Using eco-friendly materials can help in enhancing your brand standards in the competitive market and attracts eco-conscious clients. Moreover, it assists in boosting your sales and value.

“Choose TPB’s top-tier medicine packaging to meet your wellness demands.”

Place your pharmaceutical packaging boxes order today!

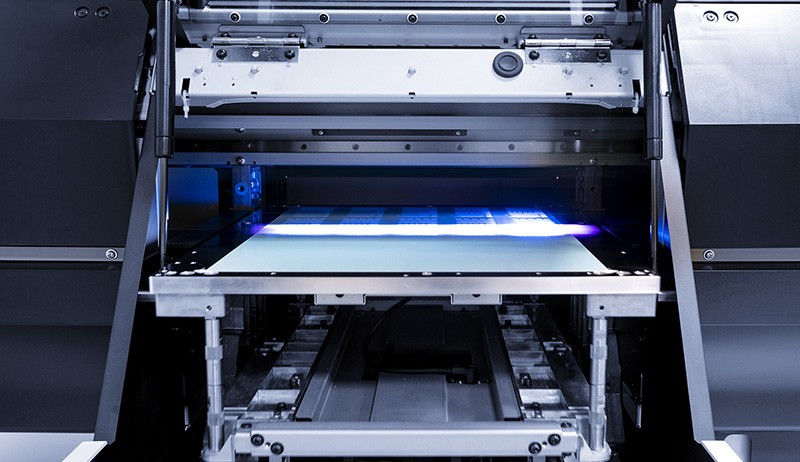

High-Quality Printing & Finishing

When it comes to pharmaceutical boxes, delivering the right information to the customer is necessary. It makes the packaging transparent for the end-users, increasing the customer’s trust in your brand. To give users a strong impression, we use quality and advanced digital, offset, and screen printing technologies. Information is printed with sustainable inks such as soy, vegetable, and water-based inks.

“Experience the power of printed pharmaceutical packing with TPB.”

Moreover, we provide gloss UV, matte UV, and spot gloss & matte UV. These improve functionality and enhance the aesthetic of the packaging.

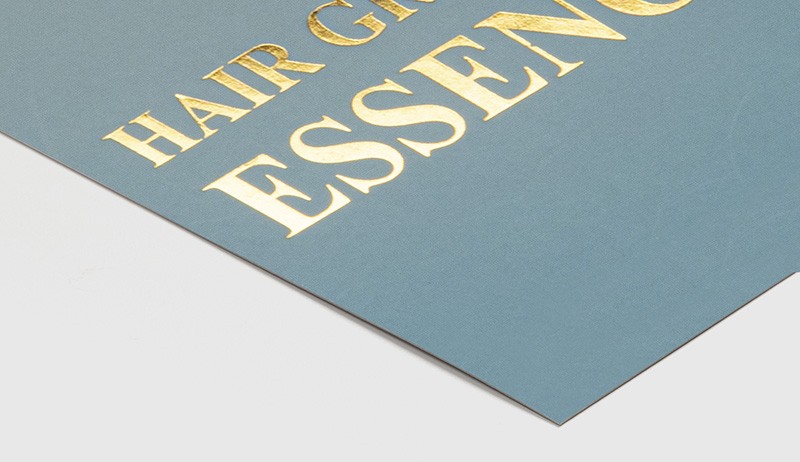

Custom Medicine Packaging Boxes with a Logo

Custom medicine packaging boxes are carefully personalized at TPB according to your company culture and requirements. Your brand logo is imprinted using eye-catching CMYK & PMS color schemes. We print titles, slogans, and important medical information for maximum brand recognition. Get a printed brand logo on your case and increase your profits.

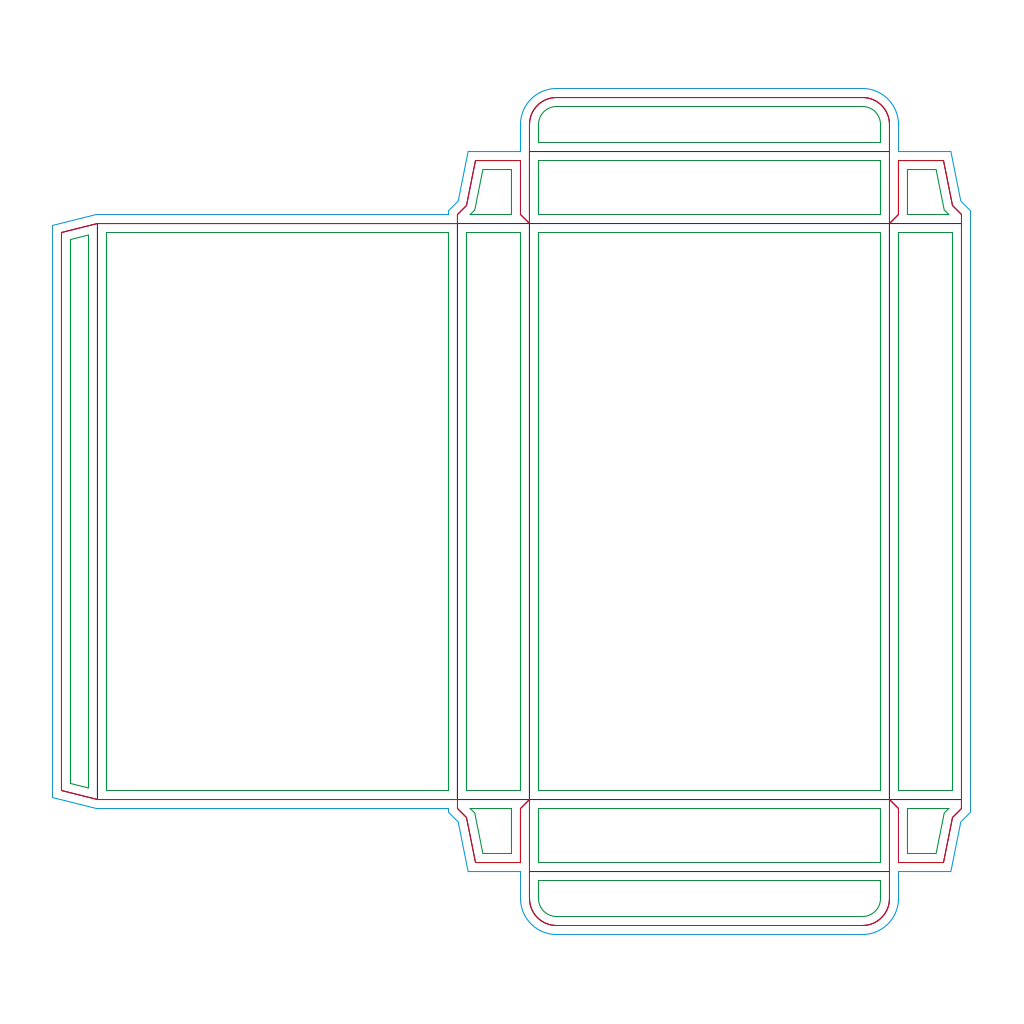

Numerous Packaging Styles

We personalize different box styles for a variety of medicines. All the styles are unique from each other. Our medical packaging case list includes window, reverse-tuck, straight-tuck, tuck end, dispenser, foldable, seal-end, sleeve, die-cut, display, and tuck top boxes. Depending on your various medications, you can choose any of the above-mentioned styles or share your ideas.

Secure Locking System

Our eco friendly pharmaceutical packaging is child-friendly and specially designed with secure closure mechanisms that do not harm the kids. Make a purchase today!

Secure Storage Compartments

Our dedicated team crafts storage sections with compartments for a variety of medical products. This gives an organized look to the numerous medicines. Customize the number of compartments according to your choice with the assistance of The Packaging Base’s skilled team.

Custom Medical Window Packaging

Showcase your medicines with our excellent die-cut window custom medical packaging. These charming windows give an attractive look, designed to maximize the sales potential.

Safety and Transparency

End-consumers are interested in knowing the details printed on the custom medication packaging. Some individuals may have allergies because the ingredients used do not suit them. Therefore, it is mandatory to mention the required details on boxes. We can also include manufacturing and expiry dates for more security which gives peace of mind to the customer. Such packaging boosts the customer’s trust and loyalty.

Main Features

Our packaging is versatile, used to pack a variety of items, and perfect for sending over a long distance. Some of the core attributes of our pharmaceutical packing are:

- Durable material

- Child-resistant packaging

- Prevent from heat & moisture

- Compliance with regulations

- Informative labeling

- Versatile packaging choices

Everything is created by taking care of the customer’s desires. Opt for it today!

Call to Action!

Our dedicated expert staff pays full attention to custom CBD medicine packaging boxes during the manufacturing process. We precisely make such packaging that meet the buyer’s demands. Fill out the quotation form to achieve the exceptional packaging demands. If you have any queries you can contact us at 818-575-6669 or sales@thepackagingbase.com to avail free consultation!

Daxon Clayton –

After exploring many companies, I found TPB the best one in terms of quality and rates. I am impressed with all the services!

CADE AYDAN –

I wanted 500 medicine boxes for my pharmacy. I received the order on time with top-tier quality. Highly recommended to you!

FREDDIE GINO –

The Packaging Base’s custom boxes are eco-friendly, which has created a strong impact on my brand. A preferable brand!