Get Custom Auto Bottom Tray Boxes at Wholesale Price

Do you want to get the best exposure by packing products in quality tray packaging? The Packaging Base is your all-in-one solution. We manufacture durable and high-strength custom auto bottom tray boxes that are a perfect blend of style and beauty. They have the strength to catch customer’s attention even when they are far away from the products.

“Increase the worth of your brand with TPB’s custom solution.”

Our packaging has some specialties; its unique design makes costumes buy from you instantly. We design auto bottom boxes with the brand’s logo which makes the individuals remember your brand. Call us today for a mesmerizing packaging journey!

Customize the Auto Bottom Tray Box with TPB

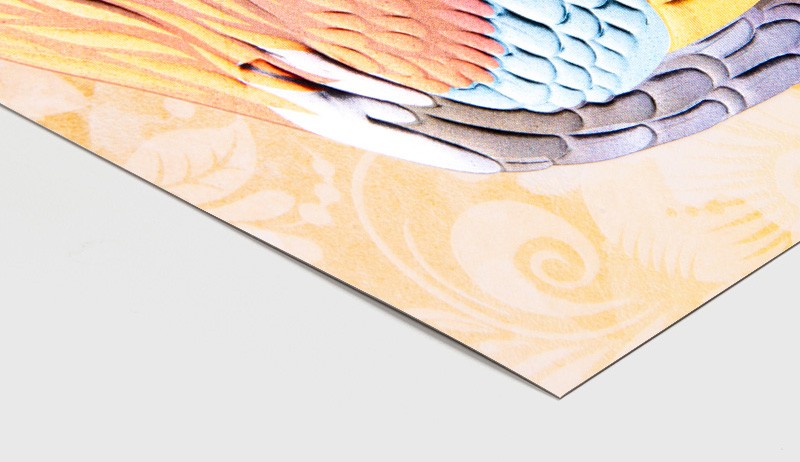

A custom printed auto bottom tray box is a peculiar choice for storing and displaying items effectively. Usage of retail goods is widely increasing at a higher rate in the industry. So, a distinctive look is necessary for retail items that have no comparison with any other box.

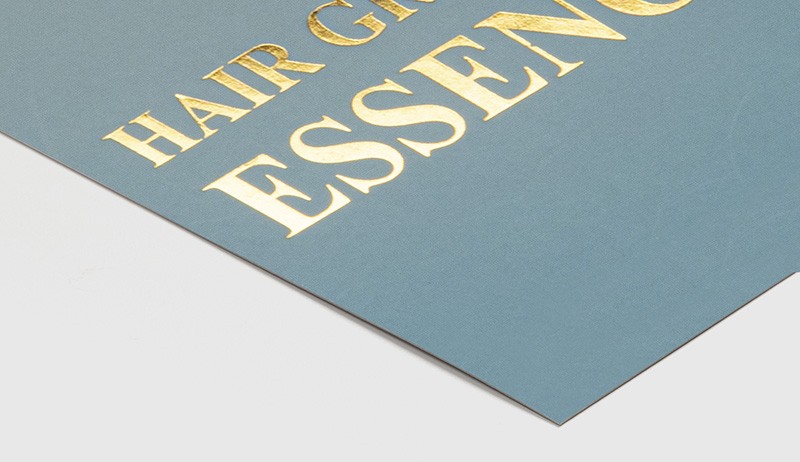

Here, you will get limitless personalization choices. You are not bound to choose from add-ons and embellishments. We are offering more than that. You can choose from any size, shape, design, foiling, embossing, debossing, and style for a premium look.

Our company has skilled staff dedicated to making affordable packaging. You just need to specify the product’s specifications and leave the rest to us. We will exceed your expectations in terms of any custom feature that you desire.

Easy Assembly – Tray Box Packaging

One of the most effective features of these tray box packaging is that they are easy to assemble and efficient. This feature saves significant time and gives ease to the buyers.

Auto Bottom Tray Boxes with Custom Printed Tags

Custom printed tags are another amazing fact, which adds grace to the packaging. We customize tags in different styles or shapes. It can be in any form like die-cut, circular, oval, rectangular, or any shape depending upon the buyer’s needs, our professional staff will make it. We print logos, prices, and discount offerings on the tags. If you ask for any other things, we will print the same for you.

Ideal Choice for Marketing – Boost Your Brand

If you are among those customers who want to make their brand remarkable and get maximum sales by connecting with a larger audience, then we are here to assist you. It is only possible when customers get to know about your brand. In order to fulfill this purpose, get in touch with TPB.

We prepare an auto bottom tray box with the logo, company name, product details, and any other marks. These brand identifications are important for brand image. We use CMYK and PMS color techniques. Get premium and colored custom product boxes with logo from us today!

Optimal Delivery Time

TPB’s standard turnaround time is 8 to 10 business days. Whenever or whatever you order, you will receive it promptly at your location. We also facilitate rush orders with a turnaround time of 6 to 8 business days.

Why Select Us?

The Packaging Base is the leading brand based in the United States that is dedicated to bringing smiles to customers’ faces. We use 100% eco-friendly stock that protects the products from harm. Our expert designers have the ability to customize top-class designs.

Our minimum order quantity is just 100 cases, and shipping is free in the whole USA. We offer significant discounts when anyone requests custom auto bottom tray boxes in bulk. We are available 24/7 to address the customer queries. Without wasting time, just call us for all your custom printed packaging boxes.

Robert Jameson –

Their product quality is consistent and available at market competitive rates. No one can compete with them. Impressive!

Jonathan Easton –

I have worked with this brand for the previous 6 years, and they have never let me down in any case. I would recommend TPB!

Weston Bennett –

I was amazingly surprised by the designs of TPB. They are well-designed, and every corner is full of creativity. Impressive!