Get a Durable Auto Bottom Box from The Packaging Base

The auto bottom box comes with pre-glued flaps at the bottom. The bottom side of these boxes is specially made with durable materials like cardboard and corrugated. These eco-friendly packaging hold the heavier items firmly. Auto bottom boxes offer versatility as they are used to pack numerous kinds of products such as beverages, food, cosmetics, medicine, apparel, retail items, beard oils, personal care products, etc.

“Save time and money with TPB’s innovative custom printed auto bottom boxes.”

We personalize different sizes of boxes ranging from 4″ x 4″ x 4″ up to 24″ x 24″ x 24″. You can also tell us if any other size you want for your specific products. Furthermore, we make your tuck top auto lock bottom box more charming with top-notch printing and labeling services.

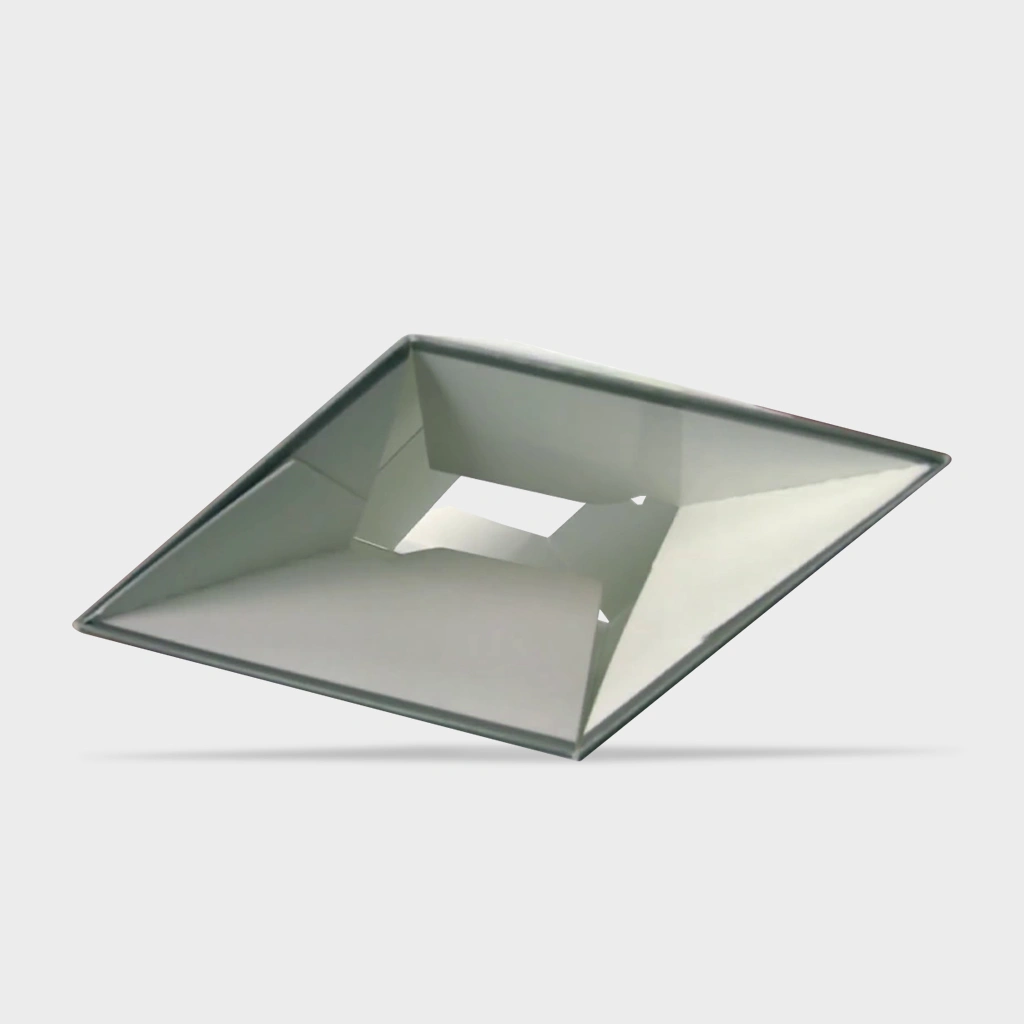

Structure, Sizing & Style of Custom Auto Bottom Box

The structure and size of the custom auto bottom box depend on the nature, height, width, and weight of the product you want to pack. You just have to describe the specifications, and we will make the high end packaging accordingly. The end products will surely meet your requirements.

We have a pool of custom packaging box styles such as tuck end auto bottom boxes, seal end auto bottom boxes, and custom auto lock bottom packaging boxes. Apart from this, you can request any custom style, height, width, or more.

We can send a flat batch of auto bottom boxes to the customer’s place upon their request, this way, the additional cost is saved.

Printed Auto Bottom Boxes with Custom Inserts

You do not need to worry about packing your delicate items, such as perfumes, oils, or serums. For this, we provide custom inserts that ensure the fragile products are safe during shipping and handling.

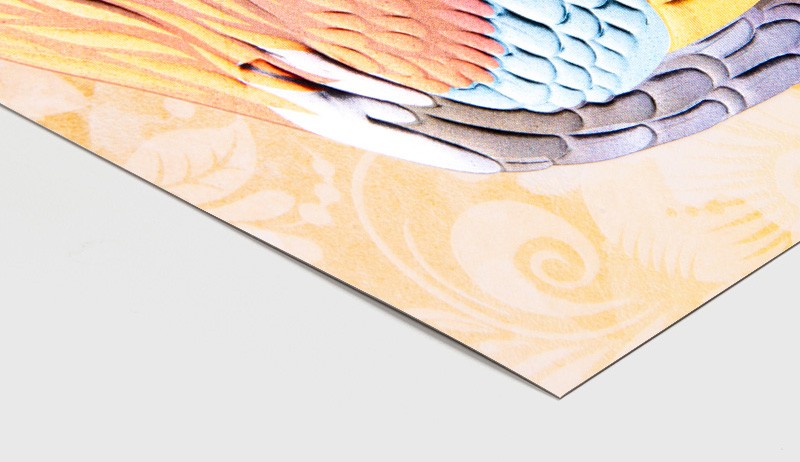

Increase the Worth of Your Products with Our Appealing Customization

These corrugated auto bottom boxes are the prime choice for retailers as they assist them in packing lightweight to heavier items. At TPB, you are free to choose any customization choice that suits your brand and add value to your products when they are placed on the shelves or held by customers.

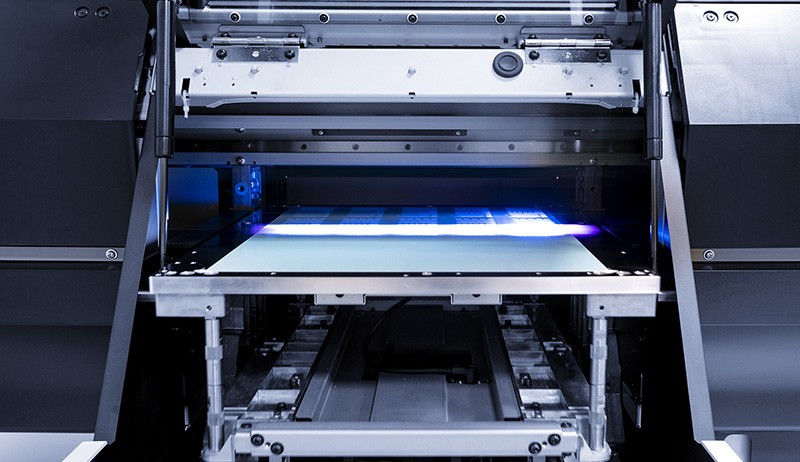

We have advanced screen, digital, and offset printing techniques along with CMYK and PMS color models. You can enhance the visibility of the auto lock bottom box with coating services.

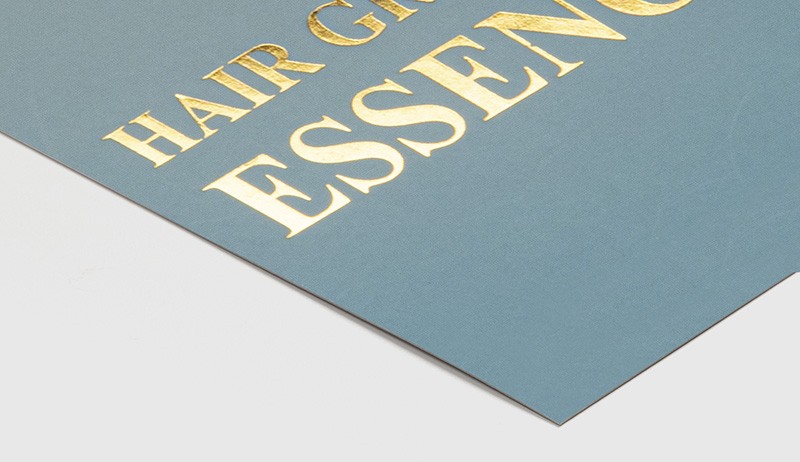

Enhance the Buyer’s Experience with Finishing

Customers only praise the packaging that captures their attention in a few seconds. We have all the qualities that grab the eyes and hearts of every passerby instantly. We guarantee that our decent finishing, for example, embossing, debossing, semi gloss AQ, gloss UV, matte UV, and spot gloss & matte UV, will make your custom auto lock bottom boxes wholesale adorable. As well as we offer custom window cutout tuck top boxes. These cutouts are unique in styles which boost the unpacking experience.

Why Join Hands with Us?

Customers are our first priority; we never let them down. We value our clients and take care of their budgets. We believe in transparent working, and everything will be clearly discussed with you. Trust us!

At The Packaging Base, we provide affordable auto lock bottom boxes. Our experienced team works with full dedication and makes every inch of the auto bottom carton innovative and special. We ship all the packaging free to the customer’s location in the USA.

Furthermore, our design services, dyes, or plates are free. You can contact us any time of the day and night, and we will quickly respond to your queries. So, don’t hesitate; to pick up your cell and contact us right now!

Karim Yehuda –

TPB is one of the best companies I have worked with. Their customer service has no comparison in the market.

Bjorn Nathanael –

I wanted to upgrade my packaging, and TPB’s team has helped me. Thank you guys; you are truly amazing.

Langston Nelson –

This company has the fastest turnaround time and great-quality packaging. My experience with them was fantastic!

Alvaro Robin –

Their design, quality, colors, and materials for tuck-bottom boxes are ideal. Every customer has complimented them.